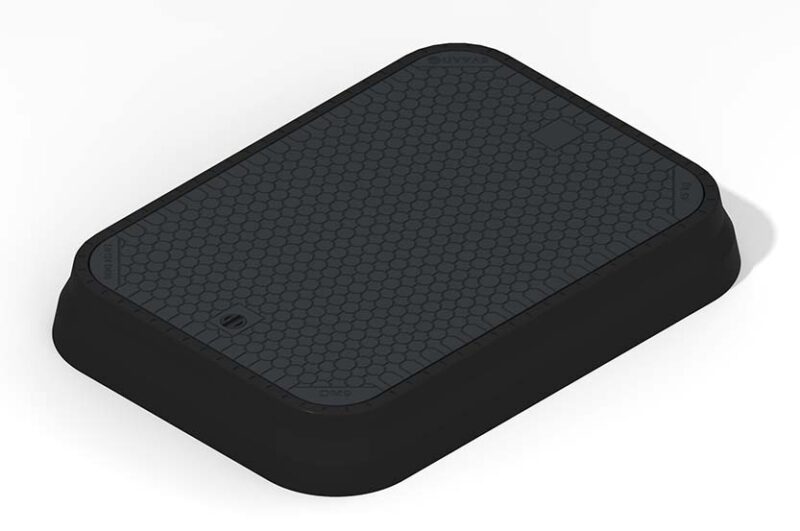

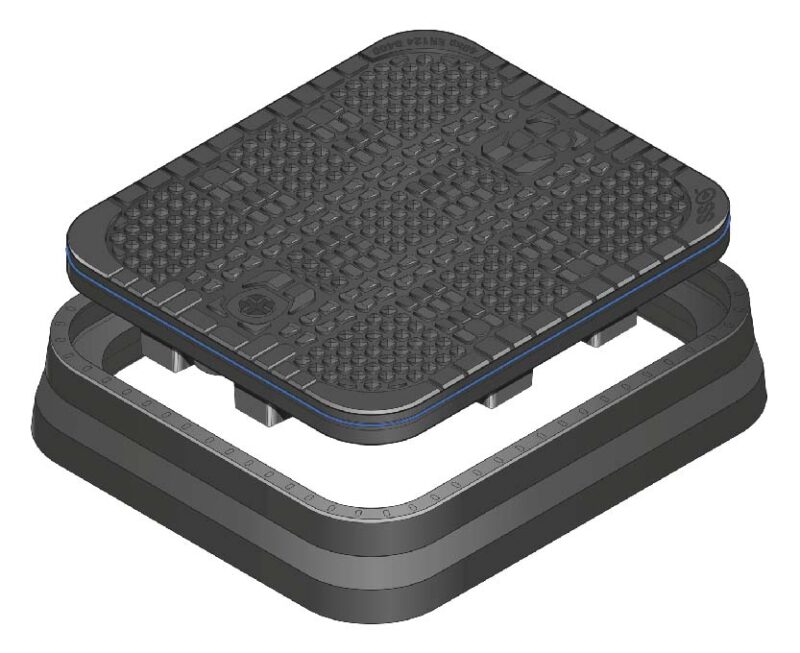

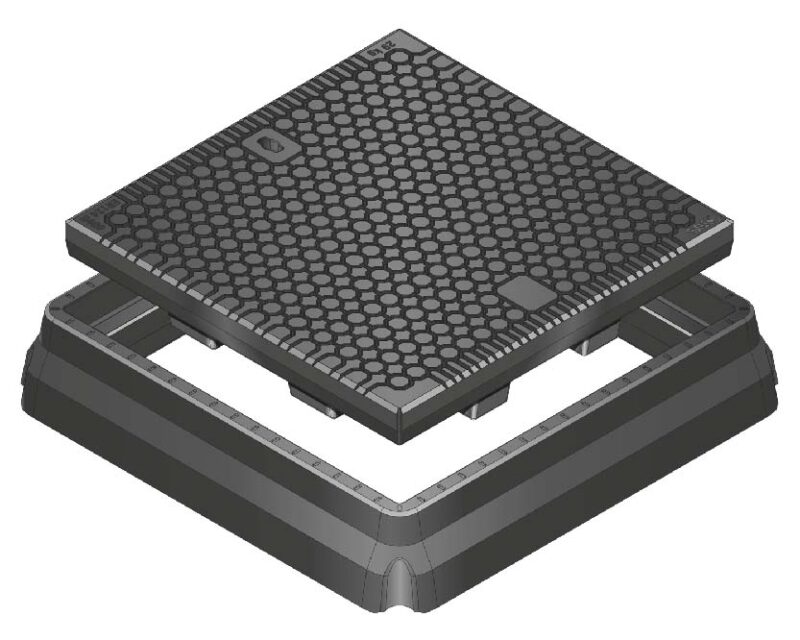

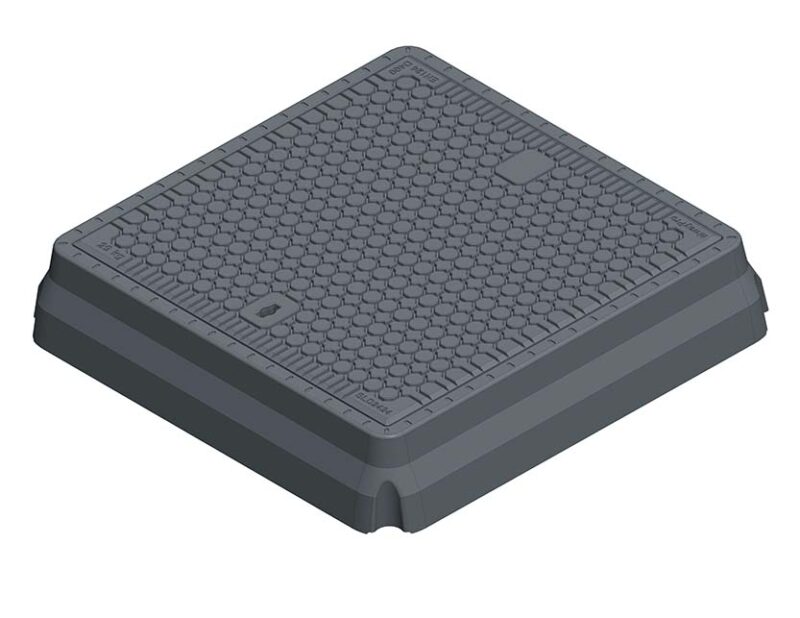

D400 Manhole Covers

D400 manhole covers for highways and parking areas

Class D400 highways or roads (including pedestrian streets), hard shoulder and parking areas, for all types of road vehicles. ThruBeam’s D400 manhole cover range has been developed to be used in highways to give optimum performance and are significantly lighter than concrete and ductile options. Our covers can be locked, sealed and made in different colours.

Technical Information

Brochures

Installation Guides

Test Reports

Get a Free Quote

Let us know your requirements and we’ll get back to you as soon as possible.