No scrap value

This is a major problem around the world with the iron and ductile covers and even frames being stolen to be “weighed in” for scrap.

There is no residual value in our covers or frames and so eliminates the reason for theft.

If you’re looking for a lightweight, strong, and long-lasting composite manhole cover or trench cover, you’ve come to the right place. ThruBeam’s patented technology leads the way in strength and durability.

Our composite covers are non-corrosive, watertight and highly secure, guaranteeing you peace of mind and protecting your investment for years to come.

ThruBeam’s lightweight composite covers are around 25% the weight of an equivalent sized concrete cover, 33% of steel/iron covers and 70% of aluminium, yet they still possess the same strength as steel. SSC covers are also up to 23% lighter than the nearest like for like performing composite cover. The benefit of lightweight manhole covers is they are easier to remove and replace.

Our lightweight composite covers make access quick and easy without compromising on strength and durability.

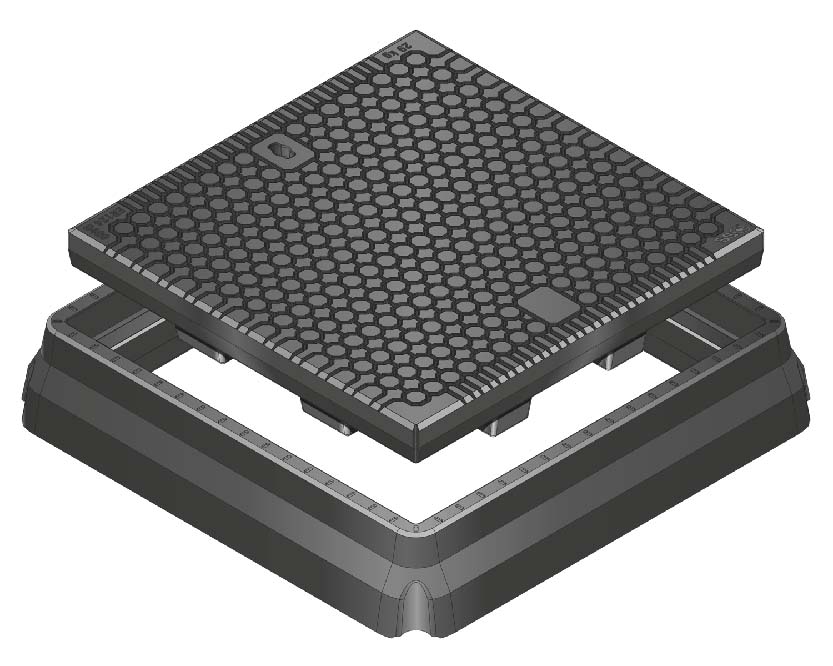

Each composite access cover and frame is built with a unique monocoque construction and produced under carefully controlled manufacturing conditions. They are one-piece products have no joints or exposed laminations and are without any form of fabrication.

Components are embedded and encapsulated at manufacturing stage to prevent environmental degradation.

The ThruBeam composite access cover is robust and will not crack, warp, chip, swell, or expand.

The stiff tensile structure resists all known forces on normal working conditions experienced on underground positions. Tensile stiffness is 4-6 times that of steel or aluminium and all are tested to the EN124:2015 standards

The properties of the composite materials enables our products to be fitted into demanding locations and used by utility companies, petrol forecourts, factories, main contractors and infrastructure developers. Check out our range of covers here.

Structural Science Composites Limited [SSC] and ThruBeam has drawn on over 20 years of knowledge in composite cover manufacture to provide the ultimate in durable manhole covers.

A leader in designing and supplying durable manhole covers for underground access. Our composite manhole solutions offer significant benefits over covers made from steel or ductile and concrete.

The main cause of fatigue is the level of induced stress in a structure deflection. If a credit card is bent back and forth it will eventually snap. That is the result of stress breaking down the structure. The material is seen to be going translucent [thinner] as the material degrades.

Our durable manhole covers are made to ensure they have a resistance to stress by a combination of design and the material it is made from.

Composites, iron and steel materials all react differently to stress induced loads depending on their elastic and plastic properties, brittleness and yield point*. These properties are important issues with regard to performance.

Steel is a very rigid so material so it experiences low deflection characteristics, but it will have permanent set above its yield point, which is well below its ultimate tensile strength. It will not fail at this point, but it will be permanently damaged

The perception is that SG iron is also very rigid but this is not the case and is likely to deflect more than a SSC composite cover. SG iron covers were introduced some years ago to combat the brittleness of grey iron and because less material can be used for a similar strength. SG iron is brittle and has no plastic deformation before reaching its ultimate tensile strength and catastrophic failure will occur

Composite materials have varying resistance to stress characteristics depending on the type of glass reinforcements used. For example carbon fibre has good rigidity, but nylon [Kevlar] has very high deflection characteristics. SSC use ‘E’ glass in a design which can accommodates the loads that would normally cause breakdown of the material and at ultimate stress level do not fail catastrophically and experience progressive failure

When the ultimate tensile strength is reached, because of the ductile property of the composite there is no catastrophic failure.

*The yield point it where a material changes from elastic deformation to plastic deformation, causing it to permanently deform. Below this all deformation is recoverable.

ThruBeam composite covers are proven and guaranteed to meet the structural and fatigue requirements of AASHTO and are fully compliant with European EN124 : 1994 regulations.

Wear is negated by the combination of the materials and design. SSC composites materials are robust and will not break under normal in-service loads. Each SSC cover has a close tolerance interface with a special torsional resistant frame (D400 Composite, B125 Aluminium), which prevents movement and distortion from the eccentric forces that are a major cause of wear and failure. A recent report by a US test house indicated that the top surface would have an estimated life of 15 to 18 years based on 15,000 Foot Contact Events on the same contact point each day for the whole period. A wear indicator is fitted to all our standard covers.

If you are looking for a supplier of composite durable manhole covers look no further.

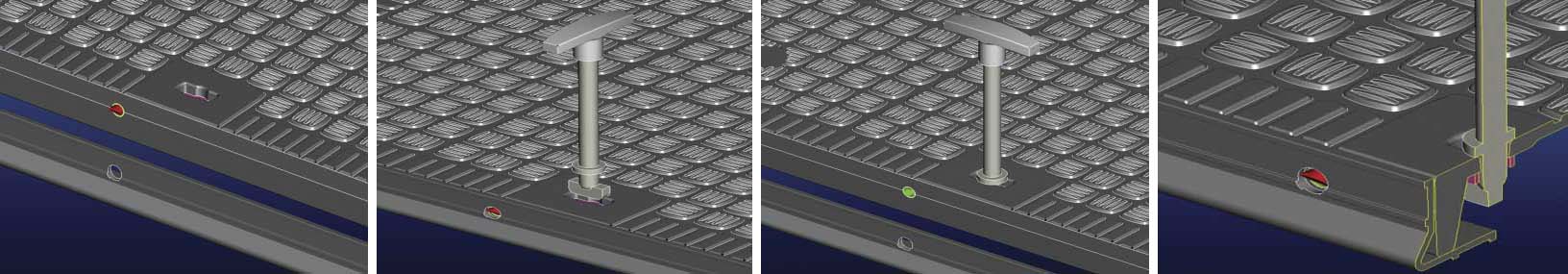

All our products have the ability to have a locking mechanism installed.

Lockable access covers not only improves site and location security and provides security against theft and malicious damage.

We supply a number of lockable access covers, we are happy to advice which would be more suitable for your needs.

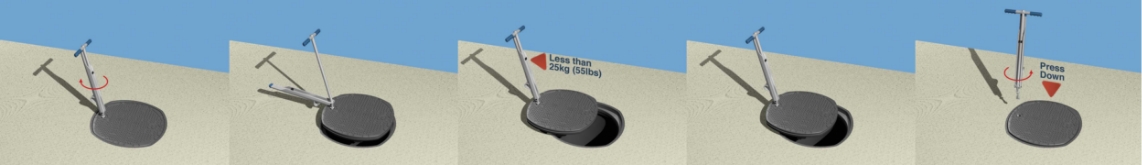

The B125 range has a locking mechanism which has been designed to re-engage automatically when pushed back into the frame.

The C250 and D400 range has an ergonomically designed key which locks and unlocks the cover from the frame.

The cover can never be left unlocked due to the way in which the key is removed from the locking mechanism, providing a failsafe system.

The frame design ensures that the surrounding concrete structure is maintained in compression, which prevents displacement and cracking. Deep seating of the lockable access covers prevents any possibility of them being disturbed by impact forces. Continuous rather than three point seating eliminates wear and the SSC round covers have rotational restraint to prevent eccentric forces from causing displacement and wear.

B125 restraint device

Cover can be quickly unlocked using a standard key to BS497 Standard or equivalent, and only requires unlocking from one end to allow ease of removal of cover from its frame. The system has been designed to allow automatic re-engagement of the restraining bolts when the cover is re-installed into its frame.

This is a major problem around the world with the iron and ductile covers and even frames being stolen to be “weighed in” for scrap.

There is no residual value in our covers or frames and so eliminates the reason for theft.

If you are looking for non-slip manhole covers look no further. The ThruBeam’s cover’s top surface material has a better slip-resistance value in a wet, dry, or worn state, than any other commercially used material and is comparable with a good highway surface.

Current specifications regarding non-slip manhole covers see Engineers asking for materials with a co-efficient of friction that is 0.50 and Health & Safety institutions consider any material of less than 0.40 as unsuitable for use in public areas.

ThruBeam composite manhole covers have a value of not less than 0.7.

Note the multi direction pattern on C250 and D400 range of products.

A recent motorcycle fatality has been attributed to a ‘slippy’ metal cover. This was measured at less than 0.40 co-efficient of friction, which is the value that Health & Safety regard as hazardous.

Slip tests for our range of covers are available here.

For further information on the safety aspect of our non-slip products, please do not hesitate to contact us.

A ThruBeam non corrosive composite cover does not react to temperature, hot or cold and in fact are inert.

A composite cover will not go rusty like metal covers, they are UV resistant and they will not react with other materials close by.

They are resistant to the elements, wind borne sand, salt, even at higher temperatures, and chemicals used in the winter months for de-icing.

Unwanted potentially destructive elements are unavoidable in the manhole environment and they have a continuous effect. The only perfect foil is an inert material. For all practical purposes a ThruBeam composite cover are effectively inert in all expected environments. They will not corrode or cause corrosion when subjected to elements such as, water, wind borne sand and salt (even at elevated temperatures).

For further information on how composite covers can help in a range of applications and environments, please do not hesitate to contact our experienced technical sales team, who can advise on the most appropriate product for your requirements.

Contact us today, for a no obligation chat. Or call 01229 814 340.

ThruBeam is the only composite manufacturer who can mould holes into certain models of their covers.

Vented covers are used to reduce the build-up of gasses/fumes under a cover and allow the gasses to escape and vent the system. This reduces the risk of any possible event taking place.

The more ventable covers that are fitted within a system will improve the venting performance.

ThruBeam has developed vented products for major electric provider companies in the US and UK.

Ventable covers are also used in the water industry to help reduce pressure build up under a cover.

Water can escape through the vents to help reduce the pressure and help avoid ‘popping’ the cover.

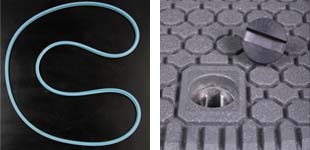

ThruBeam offers lightweight watertight covers ideal for preventing surface water infiltration. (our C250 and D400 ranges can both be made watertight.)

When the watertight versions are required a plug and silicone seal can also be supplied.

Our lightweight watertight covers are used across the country where the prevention of water/liquids is paramount such as petrol stations, telecommunications complexes and lighting networks etc.

ThruBeam have designed a “double wiper” action for their silicone seals which the first wiper cleans the frame as the cover is inserted and the second wiper makes a watertight seal.

The seal profile also contains an air void which allows the seal to make a secure contact with the frame.

This has also been tested under a 50 millilitre water head over the cover which has had a five ton weight placed in the centre of the cover.

For further information on how our watertight manhole covers can be used in specific applications and environments, please do not hesitate to contact our technical sales team for advice and guidance.

Contact us now or ring 01229 814340 today.

ThruBeam can make non-conductive and conductive covers.

A ThruBeam composite cover can have its electrical conductivity altered to suit a specific requirement. It can be made totally non-conductive for areas where electrical shock is to be negated or avoided or it can be highly conductive where static needs to be dissipated.

All materials suffer structurally as the temperature is raised and the rate of transfer of heat through the material is the critical factor in structural degradation. A ThruBeam composite cover has very low thermal conductivity (0.20 W/m dego C), which makes it a great insulator. Steel (46.0 W/m dego C) conducts heat 150 times faster than a standard composite cover.

At the National Composites Centre, it took 5 hours for a 400oF (204 oC) heat source to raise the surface temperature on the Structural Science composite cover to 125oF (51 oC). If the cover had been steel/iron of a similar depth of structure it would have taken just 2 minutes.

The benefits of poor thermal conductivity are that products are less likely to burn a person or be combustible.

For further information on any aspect of our composite products and conductivity options in particular, please do not hesitate to contact our knowledgeable technical team who will be happy to provide further advice and guidance.

Contact us now or phone 01229 814340 today.

Allows radio wave transmission

ThruBeam’s radio friendly composite manhole covers allow the transmission of radio frequency waves to pass through unhindered. We have already proven that aerials can be embedded into our composite frame which eliminates the need for long cabling and surface mounted aerials. This reduces cost and time in installation.

We are also working with companies to come up with a range of “smart covers” which can transmit data on cover movement or lifting for added security features.

This should facilitate the ability to create wireless WiFi systems for public areas at reduced cost and without the need for unsightly aerials and additional cabling. We are already working on trials of this form of facility, made possible by the use of composite manhole covers.

For further information on these products and applications please do not hesitate to contact our technical team. Call 01229 814 340 or contact us now.

Location and product identification

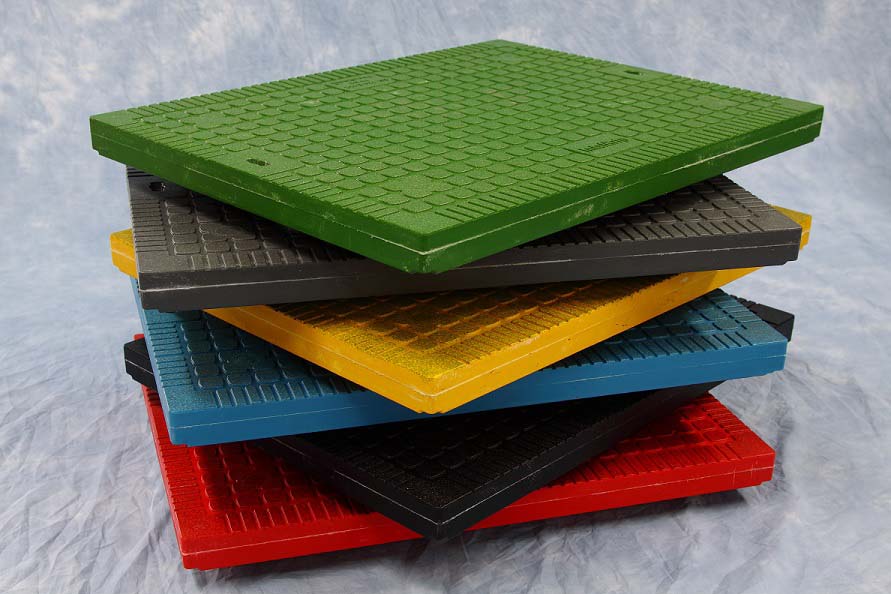

ThruBeam can manufacture and supply composite coloured manhole covers in a variety of sizes and colours.

Companies are becoming more aware of the need to identify location or products underneath covers and this provides the ideal solution.

Using coloured covers clearly helps and aids personnel in conducting inspections. The covers are lightweight and easy to raise and have non-slip properties which ensure that health and safety requirements are met, particularly in areas where moisture may be an issue.

This range of covers have been successful in a number of food factories to identity areas of high risk and low risk for cleaning purposes.

We can provide information on applications currently in place and would be happy to provide advice an guidance on how installations could be managed in these environments.

Please contact our helpful sales team for further information on our range of composite colour coded manhole covers.

At ThruBeam we believe that we provide the best products currently available on the market. The combination of the assurance of long life of the product and the quality of manufacture, give all of our customers the peace of mind knowing that once installed, our products will last.

Our Advanced Composite Covers are 3rd party tested and certified to be fully compliant with European Standard EN124:2015.

1) EN124 Compliance certificates

Class D400, Class C250 and Class BM125.

2) Pre Compliance testing

The company policy for the development of all new products is to test three consecutive products to destruction, and only when all three meet the appropriate failure load are the products then submitted for third party certification to EN 124:2015. All of our pre- compliance testing is carried out by an independent 3rd party, and test results for the specific products can be found on the following link.

3) Additional testing

In addition to EN124:2015 requirements, our product undergoes further testing to ensure that we can support the claims that we make. These additional tests are completed by 3rd party verification only. When we make any claims about our covers performance, you can have the peace of mind that a 3rd party has fully verified these claims. As a result of this we can confidently offer our product guarantee (subject to conditions). The following tests confirm the value added benefits of our product, and evidence of our products performance.

All test reports are available here

Let us know your requirements and we’ll get back to you as soon as possible.